Last month the web team were invited to take part in one of our Rack Safety Awareness courses. Inquisitive and eager to get more useful tips to pass on to you here we were delighted to sit in.

What we did

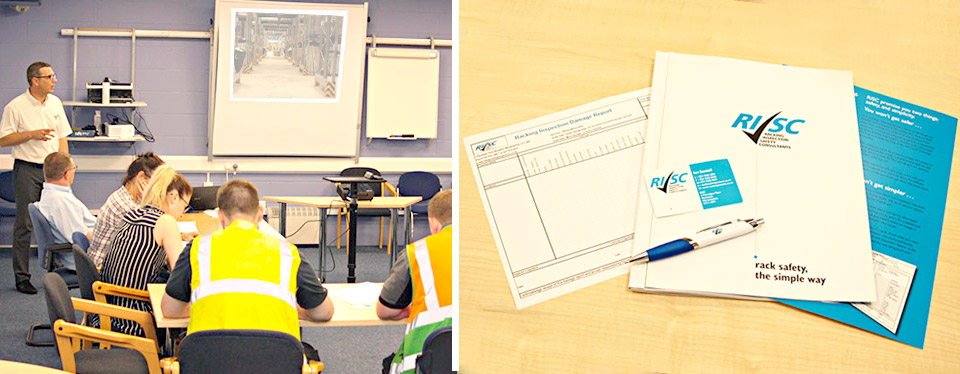

The day started at 9.30 at the Centenary Business Centre, Nuneaton, close to RISC HQ. After introductions, getting to understand everyone’s position and reasons for attending we got down to it, our training materials laid out to compliment the on screen presentation.

Right from the start, Ian, our course leader, struck a great balance between the seriousness of rack safety and it’s implications with experience and humour. He was also very keen for us to draw on our own experiences to tailor the day, making the course relevant and unique.

Getting down to it

The day was split into 4 sections all underling the two course aims; To gain a basic understanding of warehouse safety and the knowledge necessary to carry out internal racking inspections.

Before lunch

In a classroom session, Ian focusing on the basics, making sure that we were all familiar with essential ideas and terminology. This covered areas like different types of racking and components to structural awareness and the responsibilities of the racking supplier and users.

Following a short break we continued to look at types of inspection and how they might apply to our own needs and at the equipment used to help check racking.

The afternoon session

After a great lunch from local caterers provided by the Centenary Business Centre we were back in the classroom.

Ian guided us through damage classifications, examples of racking damage and in an open workshop we were encouraged to classify what we saw using the red, amber, green identification system. This really got us to test what we’d learnt and how to balance caution with practically and sound operational judgment.

The Practical

A welcome part of the course was a visit to a warehouse to put our skills to the test so hi-vis jackets on and paperwork in hand we head off for a practical session. Among the towering racking systems we were asked to check uprights and beams, check load notices, look for sacrificial legs and much more. A great opportunity to work alongside Ian seeing his experience in action.

Any Questions?

After the practical a return to the classroom saw us able to discuss our individual needs with Ian and gain insights into best practices and how best to implement what we’d learnt. A really valuable experience, putting teams on the warehouse floor in control of their environment.

Get in touch

Want to keep your team safe and racking stable? Get in touch and talk to us about your annual rack inspections and safety awareness training.